5 Best Free Online Bend Allowance Calculator Websites

Here is a list of best free online bend allowance calculator websites. Bend Allowance is a concept used in metal works and metal fabrication that indicates the length of the neutral axis between the arc length of the bend. When sheet metal is bent, the material on the inside gets compressed while the outside material gets stretched. Additional material is added to ensure that the bent metal part has the correct dimensions. Calculating the required supplementary material is known as bend allowance calculation. If you want to find out the bend allowance for a metal sheet, then check out these online bend allowance calculator websites.

Through these websites, users can quickly calculate the band allowance using bend angle, inside radius, material thickness, and k-factor values. Some of these websites can also consider the material type and material thickness to perform the band allowance calculation. Using the same set of input parameters, some of these websites can also calculate the bend deduction value. To help new users, I have included the necessary calculation steps in the description of each website.

Some of these calculators can also generate 2D and 3D representations of bent metal based on the input parameters. Plus, a good set of additional online tools and calculators are also provided by these calculators like Angle of Twist Calculator, Density Calculator, Clamping Force Calculator, etc. Go through the list to know more about these websites.

My Favorite Online Bend Allowance Calculator Website:

omnicalculator.com is my favorite website as it can calculate both bend allowance and bend deduction using the set of input parameters. Plus, it explains bend allowance and shows the bend allowance calculation formula.

You can also check out lists of best free Online Rooftop Solar Installation Calculator, Online Guitar String Tension Calculator, and Online Render Time Calculator websites.

Comparison Table:

| Features/Website Names | Can also calculate bend deductions | Considers material type in the calculation | Shows bend allowance calculation formula |

|---|---|---|---|

| omnicalculator.com | ✓ | x | ✓ |

| custompartnet.com | ✓ | x | x |

| machinemfg.com | x | x | ✓ |

| sendcutsend.com | ✓ | ✓ | x |

| trimech.com | x | ✓ | x |

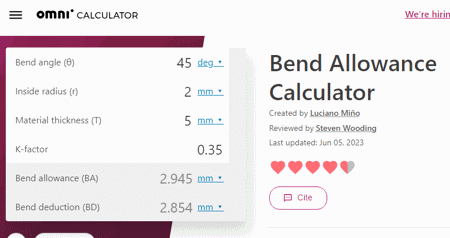

omnicalculator.com

omnicalculator.com is a free online bend allowance calculator website. Through this website, users can calculate the length of sheet metal bend. Apart from bend allowance, it can also be used to calculate the bend deduction of a metal sheet. To perform the calculation, it uses bend angle, inside radius, metal thickness, and K-factor (neutral axis position) values. Before starting the calculation process, users can specify the SI units of input parameters.

This website also explains the concept of bend allowance and shows the formula that it uses to perform bend allowance. Now, follow the below steps.

How to perform bend allowance calculator online using omnicalculator.com:

- Go to this website and access the Bend allowance calculator.

- After that, enter the Bend Angle, Inside Radius, Material Thickness, and K-factor values.

- Now, specify the bend angle unit (degrees and radians). Similarly, choose a unit for radius and material thickness parameters from available ones like mm, cm, m, in, etc.

- Next, view the calculated bend allowance and bend deduction values.

Additional Features:

- This website also offers similar online calculators such as Angle of Repose, Angle of Twist, Density, Copper Wire Weight, etc.

Final Thoughts:

It is one of the best free bend allowance calculator websites that can calculate both bend allowance and bend deduction values of a metal sheet.

| Pros | Cons |

|---|---|

| Can calculate both bend allowance and bend deductions | |

| Explains bend allowance with calculation formula |

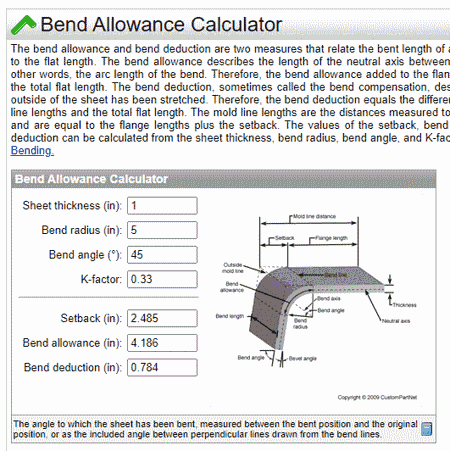

custompartnet.com

custompartnet.com is another free online bend allowance calculator website. Through this website, users can calculate the bend allowance using the known Sheet thickness (in), Bend Radius (in), Bend Angle (degrees), and K-factor values. By using the same set of input values, it also calculates Setback (in) and Bend Deductions (in) values. It also explains bend allowance and shows a diagram of a bend sheet metal with all necessary markings. Although, it doesn’t show the formula to calculate the bend allowance. Now, follow the below steps.

How to calculate bend allowance online using custompartnet.com:

- Go to this website and access the bend allowance calculator.

- After that, enter the sheet thickness, bend radius, bend angle, and K-factor values.

- Now, view the calculated bend allowance value in cinches. It also shows the setback and bend deduction values.

Additional Features:

- This website also offers additional tools such as clamping force calculator, cooling time calculator, turning horsepower calculator, wipe bending force calculator, etc.

Final Thoughts:

It is another good online bend allowance calculator website that offers all the tools to quickly calculate the bending allowance and bending deduction values.

| Pros | Cons |

|---|---|

| Can calculate bend allowance, bend deductions, and setback values | |

| Explains bend allowance |

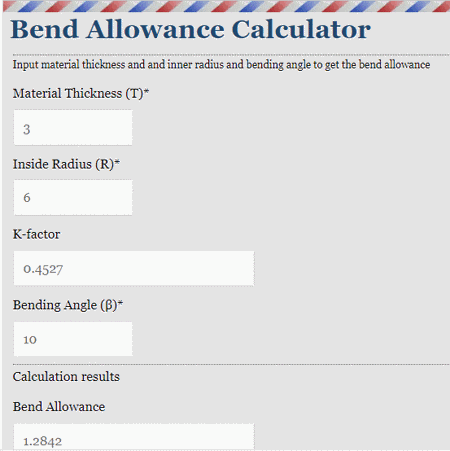

machinemfg.com

machinemfg.com is another free online bend allowance calculator website. This website not only calculates the bend allowance but also explains bend allowance in detail. It also offers bend allowance charts for steel, aluminum, and copper metals. It also shows the bend allowance formula that it uses to find out the bend allowance of a metal sheet. To perform the bend allowance, users need to submit the values of material thickness, inside radius, k-factor, and bending angle parameters. However, it doesn’t allow users to manually specify the units of input parameters. Now, follow the below steps.

How to calculate bending allowance online using machinemfg.com:

- Launch this website and access its Bend Allowance Calculator.

- After that, submit material thickness, inside radius, k-factor, and bending angle values.

- Next, let this calculator perform the calculation.

- Finally, view the calculated bending allowance value.

Additional Features:

- This website also offers calculation tools and information related to Laser Cutting, laser Welding, Mechanical, Grooving, Metals, etc., fields.

Final Thoughts:

It is another good online bend allowance calculator website through which users can calculate the bend allowance value of a metal sheet.

| Pros | Cons |

|---|---|

| Shows bend allowance calculation formula | |

| Provides bend allowance charts for steel, aluminum, and copper metals |

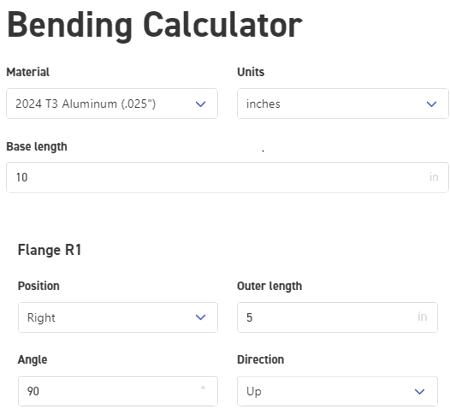

sendcutsend.com

sendcutsend.com is another free online bend allowance calculator website. Through this website, users can calculate the bending allowance for different metal types (Aluminum, Chromoly, Mild Steel, etc. )and metal thickness (.25, .50, .63, etc.). It also considers the base length and flang parameters (position, outer length, angle, and direction) to calculate the bend allowance. This tool can also calculate the bend deductions using the same set of input parameters. Based on the calculated bend allowance and bend deduction values, it is a 2D sketch and 3D diagram of the bend metal. Now, follow the below steps.

How to calculate bend allowance online using sendcutsend.com:

- Visit this website using the given link.

- After that, access the bending calculator.

- Next, specify material and thickness values.

- Now, specify the base length and flang details.

- Finally, view the calculated bending allowance and bending deduction values.

Additional Features:

- This website offers multiple online services like Laser Cutting, CNC Routing, Waterjet Cutting, Bending and forming, Power Coating, etc.

Final Thoughts:

It is another good online bend allowance calculator website that also generates a 2D & 3D representation of the bend metal.

| Pros | Cons |

|---|---|

| Can also calculate bending deductions | |

| Generates 2D & 3D representations of a bent metal |

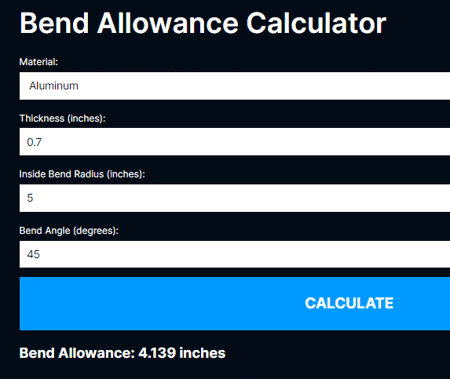

trimech.com

trimech.com is yet another free online bend allowance calculator website. This website can consider the material in its bend allowance calculation. Some of the materials that it supports are Aluminium, Steel, Stainless Steel, Copper, Brass, Titanium, etc. Besides this, it also requires thickness, inside bend radius, and bend angle values to calculate the bend allowance. Although, it doesn’t let users adjust the SI units of input parameters. Now, follow the below steps.

How to calculate bend allowance online using trimech.com:

- Visit this website and access the Bend Allowance Calculator.

- After that, choose a material from the material menu.

- Next, specify the thickness (in), inside bend radius (in), and bend angle (degrees) values.

- Finally, click on the Calculate button to view the bend allowance value in inches.

Additional Features:

- This website offers multiple online services like Business Automation, Design, Documentation, Electrical, DOD, 3D Printing, etc.

Final Thoughts:

It is a simple and effective online bend allowance calculator website that considers the material type in the calculation.

| Pros | Cons |

|---|---|

| Considers material type in the calculation |

Frequently Asked Questions

To calculate the bending allowance for a sheet metal part, you can use the following formula: Bending Allowance (BA) = [(π/180) × Bend Angle] × (Inside Radius + K × Material Thickness). You can also check out the above mentioned bend allowance calculator websites to quickly find out the bend allowance value.

The formula for calculating the bend allowance for steel, or any other material, is the same as the general formula mentioned earlier: Bending Allowance (BA) = [(π/180) × Bend Angle] × (Inside Radius + K × Material Thickness)

he primary purpose of calculating the bend allowance is to ensure that the finished metal part has the correct dimensions and shape after the bending process. Bending stretches the outer surface of the material and compresses the inner surface, affecting the overall dimensions of the part. By calculating the bend allowance, you can account for this deformation and make sure the final part meets the design specifications.

The K factor, also known as the neutral axis factor or simply "K," is a constant used in sheet metal bending calculations to account for the stretching and compressing of material during the bending process. It is a critical parameter for accurately determining the bend allowance or bend deduction. The K factor takes into account the material's behavior, the bend radius, and the material thickness.

The K factor, or neutral axis factor, for a 90-degree bend is typically 0.5. In sheet metal bending calculations, this value is often used as a general approximation for a 90-degree bend, especially when using air bending techniques. However, it's important to note that the actual K factor can vary depending on factors such as the material being bent, the bend radius, and the specific bending method used.

Naveen Kushwaha

Passionate about tech and science, always look for new tech solutions that can help me and others.

About Us

We are the team behind some of the most popular tech blogs, like: I LoveFree Software and Windows 8 Freeware.

More About UsArchives

- May 2024

- April 2024

- March 2024

- February 2024

- January 2024

- December 2023

- November 2023

- October 2023

- September 2023

- August 2023

- July 2023

- June 2023

- May 2023

- April 2023

- March 2023

- February 2023

- January 2023

- December 2022

- November 2022

- October 2022

- September 2022

- August 2022

- July 2022

- June 2022

- May 2022

- April 2022

- March 2022

- February 2022

- January 2022

- December 2021

- November 2021

- October 2021

- September 2021

- August 2021

- July 2021

- June 2021

- May 2021

- April 2021

- March 2021

- February 2021

- January 2021

- December 2020

- November 2020

- October 2020

- September 2020

- August 2020

- July 2020

- June 2020

- May 2020

- April 2020

- March 2020

- February 2020

- January 2020

- December 2019

- November 2019

- October 2019

- September 2019

- August 2019

- July 2019

- June 2019

- May 2019

- April 2019

- March 2019

- February 2019

- January 2019

- December 2018

- November 2018

- October 2018

- September 2018

- August 2018

- July 2018

- June 2018

- May 2018

- April 2018

- March 2018

- February 2018

- January 2018

- December 2017

- November 2017

- October 2017

- September 2017

- August 2017

- July 2017

- June 2017

- May 2017

- April 2017

- March 2017

- February 2017

- January 2017

- December 2016

- November 2016

- October 2016

- September 2016

- August 2016

- July 2016

- June 2016

- May 2016

- April 2016

- March 2016

- February 2016

- January 2016

- December 2015

- November 2015

- October 2015

- September 2015

- August 2015

- July 2015

- June 2015

- May 2015

- April 2015

- March 2015

- February 2015

- January 2015

- December 2014

- November 2014

- October 2014

- September 2014

- August 2014

- July 2014

- June 2014

- May 2014

- April 2014

- March 2014