6 Best Free 3D Printing Software for Windows

Here is a list of best free 3D printing software for Windows. In 3D printing, you can send print instructions or G-Code to a 3D printer to print the desired 3D object. It is a really good way to create complex designs only by using a computer and a 3D printer.

In these software, you can input and view a 3D model file of STL, X3D, 3MF, G-File, OBJ, etc. formats. According to input 3D model file, these software prepares slices or basically the design instruction for the printer. After that, you can define important printing parameters like printing material, temperature, layer height, wall thickness, top thickness, infill density, etc. There are more parameters that you might need to specify according to different 3D printer software. Lastly, you can send instructions to your 3D printer to start the 3D printing process. Besides this, you can also save the instructions as G-Code and the design as STL, 3DS, OBJ, etc. formats.

My favorite 3D printing software for Windows:

Slic3r is my favorite 3D printing software because it simplifies the overall 3D printing process. Still, it does not leave out any important option which may be essential to create proper printing instructions. Plus, this software also lets you save the Slice and G-Code of a model which you can again use in future.

You can also check out lists of best free 3D Data Visualizer, 3D Rendering, and 3D Animation software for Windows.

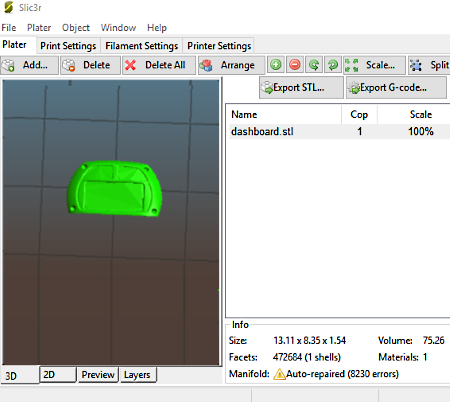

Slic3r

Slic3r is a free 3D printing software for Windows. This software helps you print an input 3D model by providing essential printing instruction to a 3D printer. In it, you can input 3D models of STL, OBJ, and AMF formats. The imported 3D model can immediately be previewed in its Plater section, where you also get options to view the model in 2D and Layer formats. Now, to prepare the printer for 3D printing, first, go to its Print Settings and define parameters like layer height, solid layers, fill density, fill patterns, pattern spacing, support material, etc. After that, go to Filament and Printer Settings to define further parameters such as Extruder Temperature, Filament Diameter, Bed Shape, Nozzle Diameter, etc. After all specifying all the parameters, you can send instructions to your 3D printer to start the printing process.

This software also lets you export the model in G-Code, STL, and AMF file formats. Plus, it even lets you save the slice of your 3D model as SVG file. Overall, it is a handy 3D printer software for Windows, Mac, and Linux.

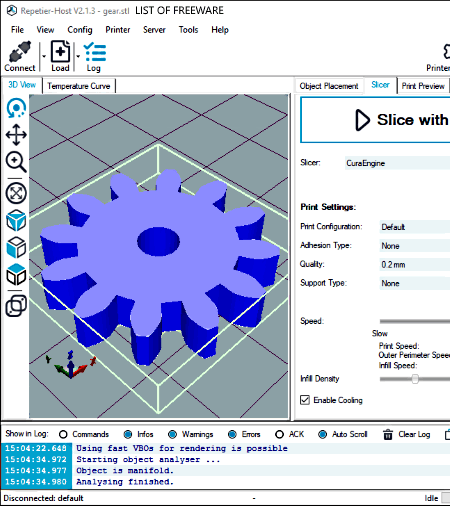

Repetier Host

Repetier Host is another free 3D printing software for Windows. It is a really good 3D printing software through which you can give print instructions to a 3D printer. Like other similar software, this one can also take 3D models as input and slice them to prepare the G-code instructions for a 3D printer. However, it also has a unique quality which is its ability to provide manual controls of a 3D printer on the interface. The basic process of 3D model printing consists of four steps namely Object Placement, Slice, Preview, and Print.

Let’s take a look at all four steps to print a 3D model:

- Object Placement: In this step, you need to import a 3D model of STL, AMF, OBJ, 3DS, AST, etc. formats. After that, place, scale, rotate, or duplicate the model on the virtual bed according to your design.

- Slice: In this step, you need to specify various slicing parameters like Speed, Infill Density, Adhesion Type, Filament Setting, Quality, etc.

- Preview: Using its Preview section, you can preview print region, model layers, printing statistics, etc., before starting the 3D printing process.

- Print: In this last step, you just need to send the printing instructions to a 3D printer via a host, USB, or TCP connection, or through Repetier-Server to start the printing process.

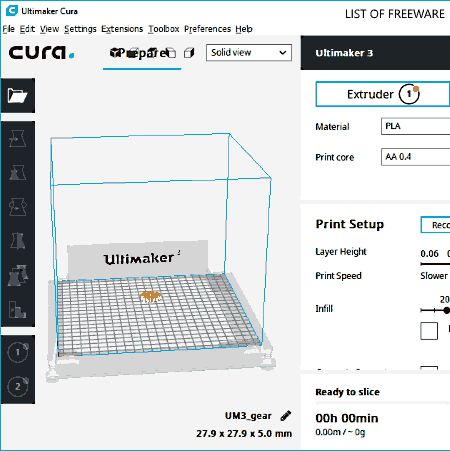

Ultimaker Cura

Ultimaker Cura is a free and open source 3D printing software for Windows. It is specially designed to work with Ultimaker Cura 3D Printers. Using this software, you can easily load a 3D object file of 3MF, G-File, X3D, STL, BMP, PNG, etc. formats. According to the input 3D model, it quickly prepares slices of your model and prepares it for printing. Before printing the model, you can preview it, scale it, and adjust various settings as you like. On its Prepare Section, you can view your 3D model and its placement inside a virtual 3D printer. Now, use its Print Setup menu to adjust print parameters like printing temperature, blue plate temperature, material type, layer height, wall thickness, top thickness, infill density, etc. After all the setup, you can start the printing process. During the printing, you can use its monitor section to monitor the progress of the 3D printing process. Overall, it is another easy to use 3D printing software.

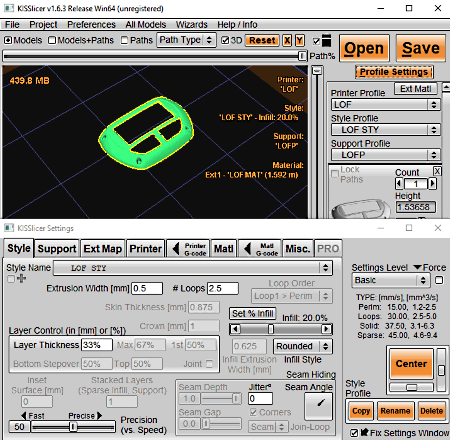

KISSlicer

KISSlicer is yet another free 3D printing software for Windows. Using this software, you can quickly generate G-code according to the input 3D model. You can use the generated G-code in any 3D printer to print a 3D object.

In this software, you can only input 3D models of STL file format. When you load a model, you can immediately view it over a virtual 3D printer bed. On the right side of the interface, you get a Profile Setting using which you can replicate multiple copies of a model to print multiple 3D objects together. Apart from the model, you can select the Models+Path option to view the 3D model along with the printing path of the extruder. An option to only view the extruder printing path is also available. Now, use its Wizards Menu to perform all necessary printer and material information to initialize the printing process.

In the Wizards menu, you get two sections namely Create Profile Wizard and Tuning Wizard. Its Create Profile wizard is used to specify all parameters related to the printer, material, style, and support. The Tuning Wizard is used to tune the function of Z like temperature, flow rate, destring length, G-Code Token, etc. After the setup, save the Gcode to print the 3D model.

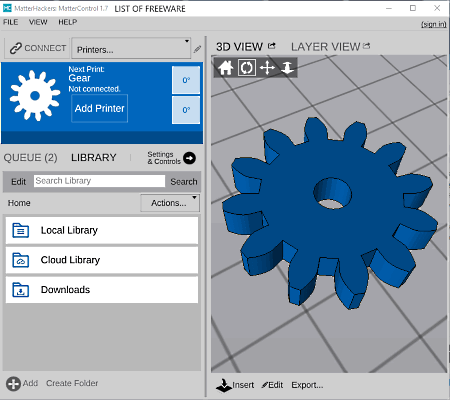

MatterControl

MatterControl is another free and open source 3D printing software for Windows. It is a simple and straightforward 3D printing software that supports 3D printers of various companies like 3D Cloner, 3D Factory, Airwolf 3D, BCN3D, etc.

In order to print a 3D model, first, import a 3D model file of STL, AMF, ZIP, G-Code, etc. The imported model can be viewed in the standard 3D format along with its Layer format in its 3D View and Layer View sections, respectively. After viewing the model, go to its Settings menu and setup up printing parameters like Material Type, Quality, Fill Density, Layer Height, etc. After setting up all the parameters, you can start the 3D printing process by transferring the printing information to your 3D printer. During the printing, you can keep an eye on the printing process from its interface. This software also lets you track the printing process by accessing the Matterhackers account from anywhere.

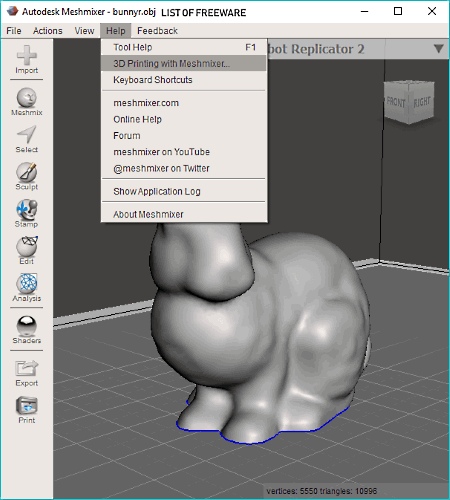

Autodesk Meshmixer

Autodesk Meshmixer is the next free 3D printing software for Windows. It is mainly a 3D model creation and editing software. In it, you can create a model from scratch and also import 3D models of STL, OBJ, AMF, PLY, 3MF, etc. formats. To create and edit 3D models, it comes with various designing and modeling tools like Selection Tools, Editing Tools, Sculpt Tools, Stamp Tools, Shader Tools, etc. The selection tools let you erase, fill, re-mesh, extract, bridge, join, and separate the selections. Selections can be converted to solid part, stamp, or open part. The editing tools let you easily apply changes to a design. These tools let you mirror, duplicate, transform, align, plane cut, make solid, hollow, make slice, add tube, and unwrap. The Sculpt and Stamp tools are equally helpful in 3D designing.

After designing and editing of a 3D model, you can print it using the 3D printing option. Its printing option also shows you all the instruction to print your 3D model. In the instruction, you get five simple steps to print a 3D object. The first step is to select a printer and then choose the material that you want to use to build your 3D object. After that, use the transform tool to move, rotate, and scale your model, and also to move the platform. In the next step, use the repair tool to check the strength, stability, and slicing algorithms. The last step is to add the support structure and start the printing process.

Naveen Kushwaha

Passionate about tech and science, always look for new tech solutions that can help me and others.

About Us

We are the team behind some of the most popular tech blogs, like: I LoveFree Software and Windows 8 Freeware.

More About UsArchives

- May 2024

- April 2024

- March 2024

- February 2024

- January 2024

- December 2023

- November 2023

- October 2023

- September 2023

- August 2023

- July 2023

- June 2023

- May 2023

- April 2023

- March 2023

- February 2023

- January 2023

- December 2022

- November 2022

- October 2022

- September 2022

- August 2022

- July 2022

- June 2022

- May 2022

- April 2022

- March 2022

- February 2022

- January 2022

- December 2021

- November 2021

- October 2021

- September 2021

- August 2021

- July 2021

- June 2021

- May 2021

- April 2021

- March 2021

- February 2021

- January 2021

- December 2020

- November 2020

- October 2020

- September 2020

- August 2020

- July 2020

- June 2020

- May 2020

- April 2020

- March 2020

- February 2020

- January 2020

- December 2019

- November 2019

- October 2019

- September 2019

- August 2019

- July 2019

- June 2019

- May 2019

- April 2019

- March 2019

- February 2019

- January 2019

- December 2018

- November 2018

- October 2018

- September 2018

- August 2018

- July 2018

- June 2018

- May 2018

- April 2018

- March 2018

- February 2018

- January 2018

- December 2017

- November 2017

- October 2017

- September 2017

- August 2017

- July 2017

- June 2017

- May 2017

- April 2017

- March 2017

- February 2017

- January 2017

- December 2016

- November 2016

- October 2016

- September 2016

- August 2016

- July 2016

- June 2016

- May 2016

- April 2016

- March 2016

- February 2016

- January 2016

- December 2015

- November 2015

- October 2015

- September 2015

- August 2015

- July 2015

- June 2015

- May 2015

- April 2015

- March 2015

- February 2015

- January 2015

- December 2014

- November 2014

- October 2014

- September 2014

- August 2014

- July 2014

- June 2014

- May 2014

- April 2014

- March 2014